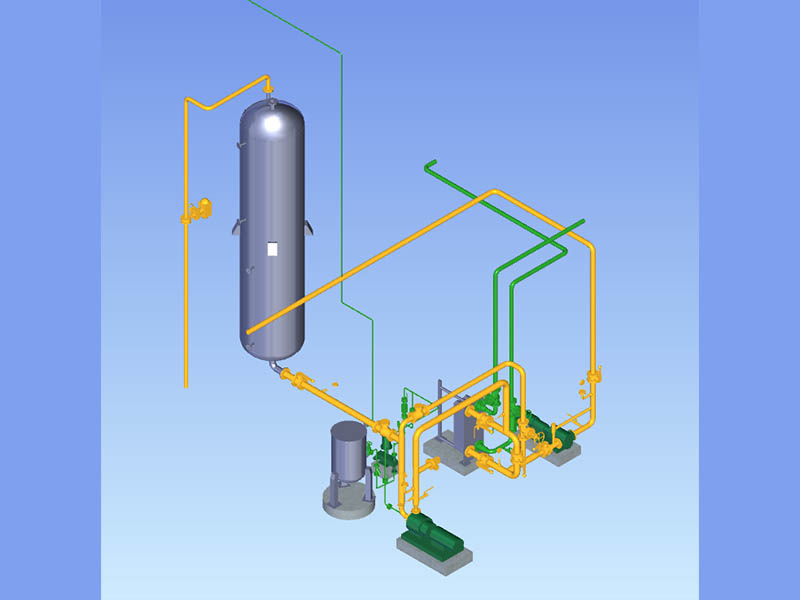

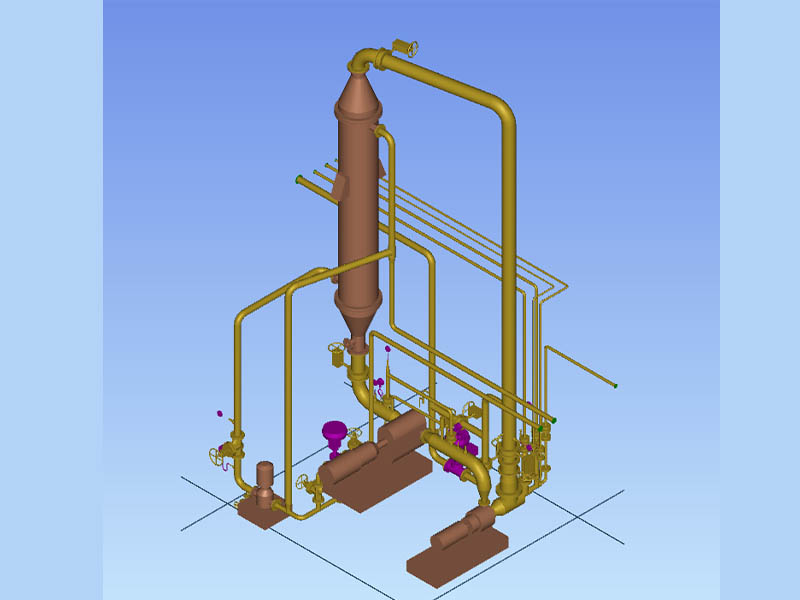

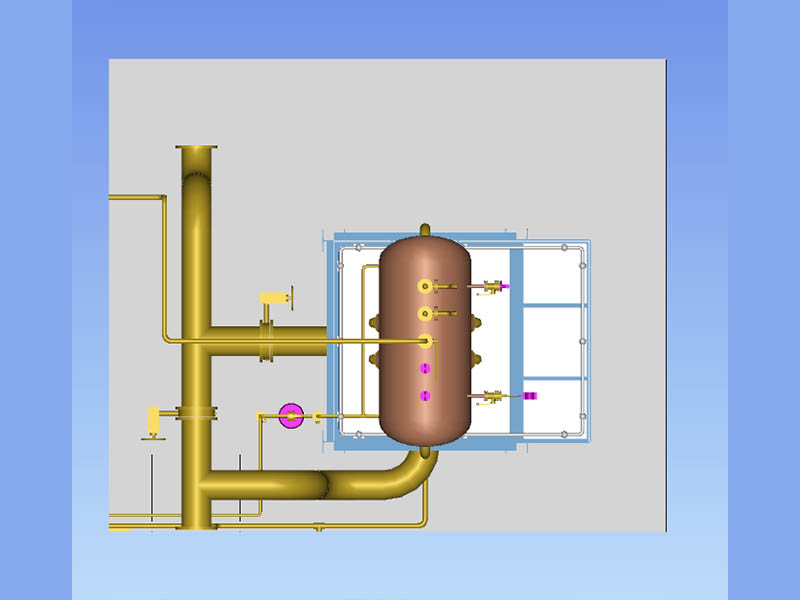

Liquid or solid sulfur goes into pipelines insulated by steam coil and jacket, then introduced to the sulfur melting tank, afterwards pumped to the high-level tank and continues transfer to the sulfur burner by submerged gear pump or gear pump insulated by the steam jacket. By adopting the mass-flow meter and VFD of the gear pump, the flow of liquid sulfur is controlled at a stable rate.

Features: WEIXIAN liquid sulfur gear pump won't be blocked by impurities and the flow rate of liquid sulfur is controlled by the mass flow meter and VFD, so the flow is stable and accurate; also achieves online operation parameters readable, which provides the best convenience for controlling SO3 concentration, plant performance adjustment and products switching.

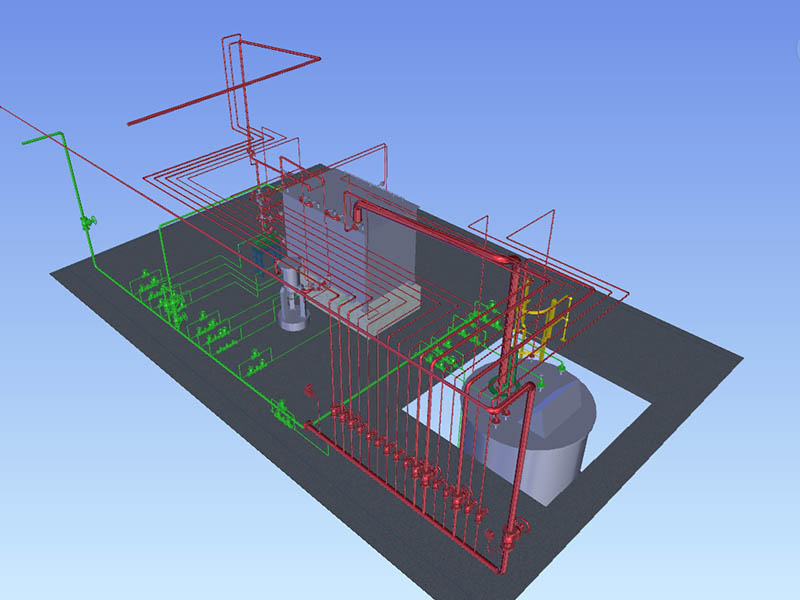

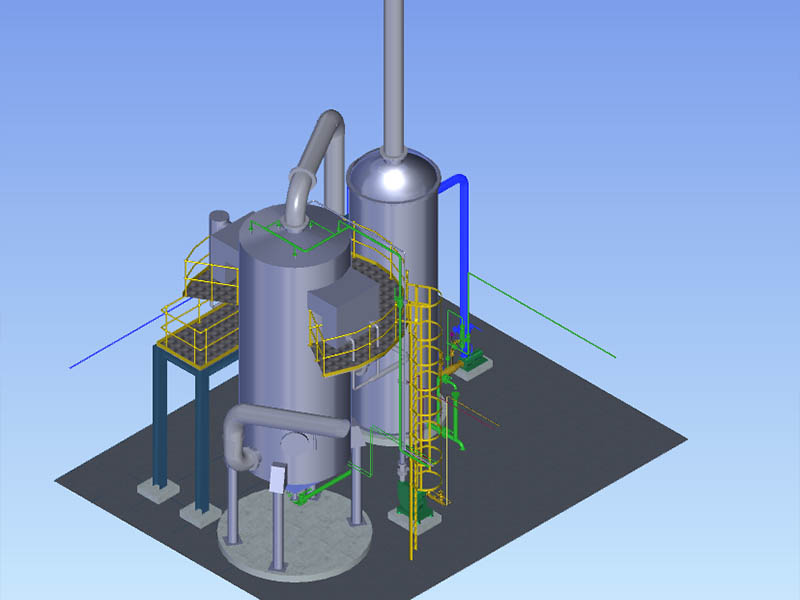

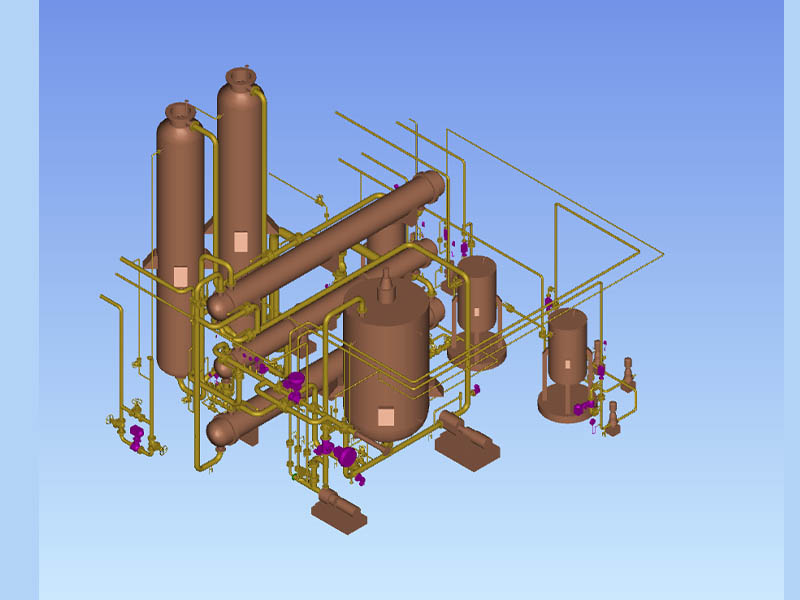

The air from the atmosphere is compressed by the main blower and transferred to a dehumidifier, then remove most moisture by water cooling and chilling, after then the air goes to silica gel for deep de-humidification, and finally gets dry air with dew point of -60℃. The flow rate of dry air (Nm3/h or kg/h) is controlled by the speed of the main blower (through the orifice flow meter and main blower VFD).

Features: The air cooling fin type heat exchanger uses SS304 as the fin plate and tube, the working life is much longer than the copper tube and aluminum plate.

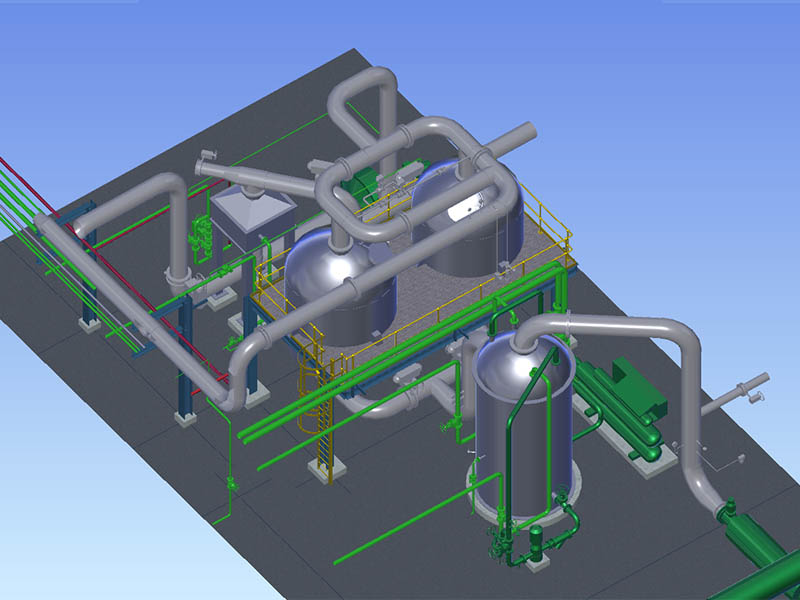

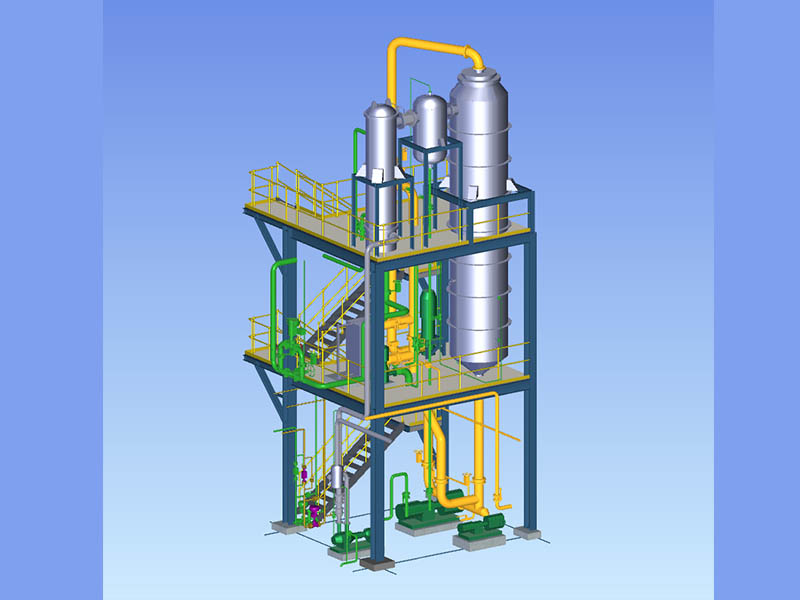

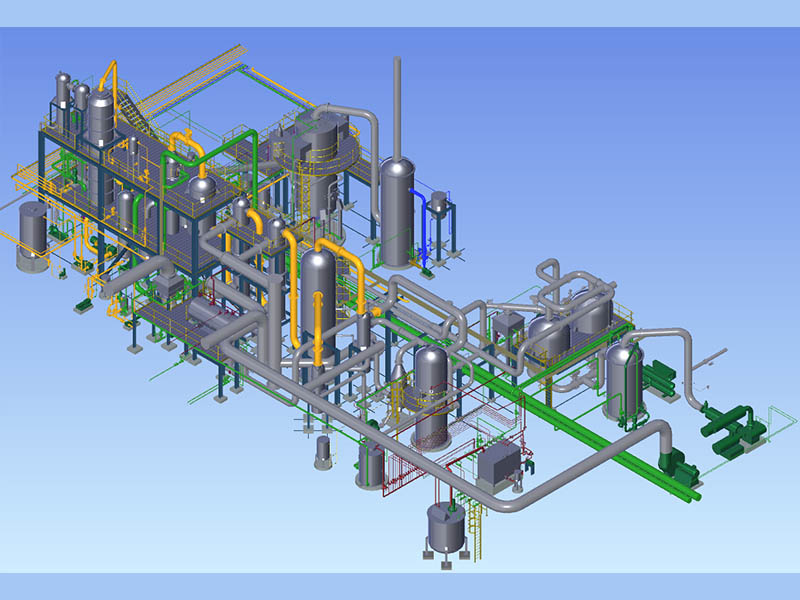

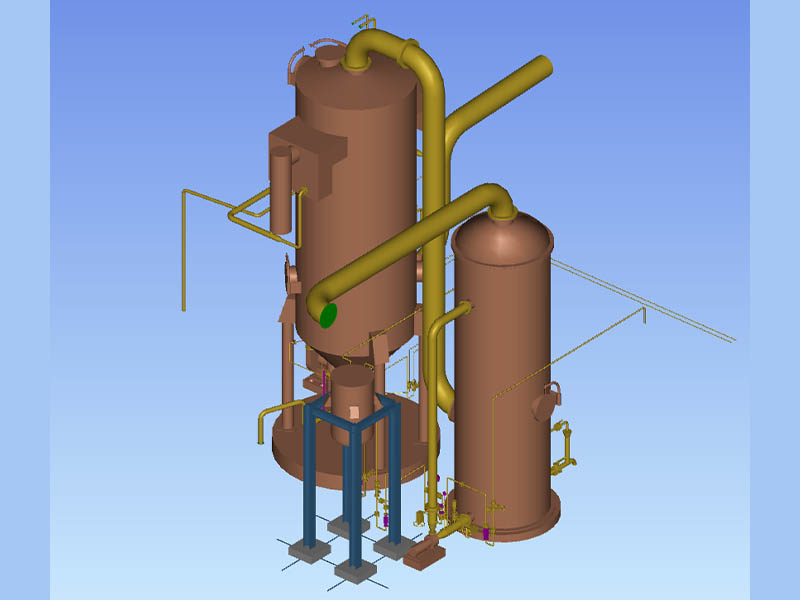

Liquid sulfur goes to the sulfur burner by precise measurement and fully combusts with dry air to generate SO₂; after cooling, SO₂ gas goes to the converter and convert to SO₃ by vanadium catalyst. After cooling, SO₃ gas goes to sulphonation/sulfation unit; SO₂ and SO₃ gas are cooled by cooling air through tube type heat exchanger; after heat exchanging, the hot air generated in this process is collected and goes to waste heat recovery unit to produce steam and hot water; the secondary hot air will be used for silica gel regeneration and scrubber wastewater evaporation & crystallization in Unit 38.

Features: SO₂ cooler adopts inlet end insulation protection and floating type design, which avoids intergranular corrosion of stainless steel above 600℃, thus the working life can be extended twice as before. By combining the start-up pre-heater and waste heat recovery unit, when preheating the converter, the steam produced also can be used for sulfur melting and generating hot water, so that WEIXIAN plants don't require any external steam.

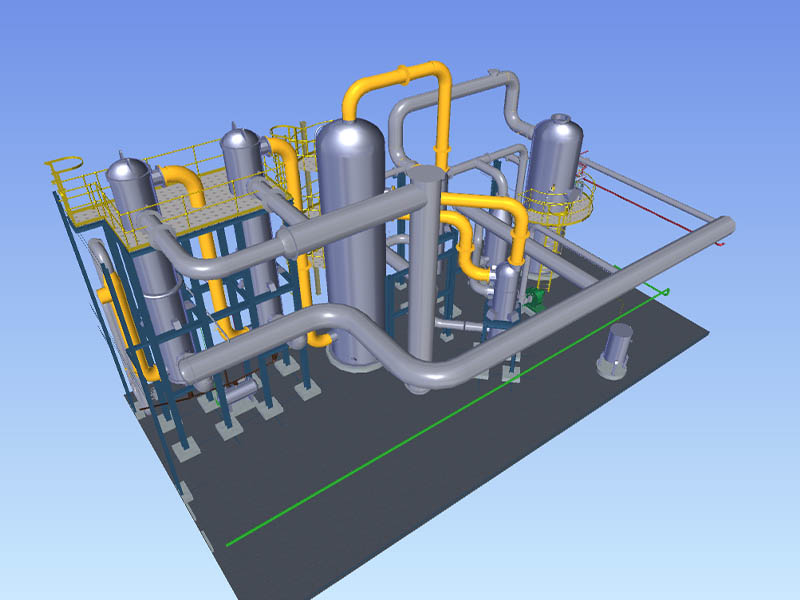

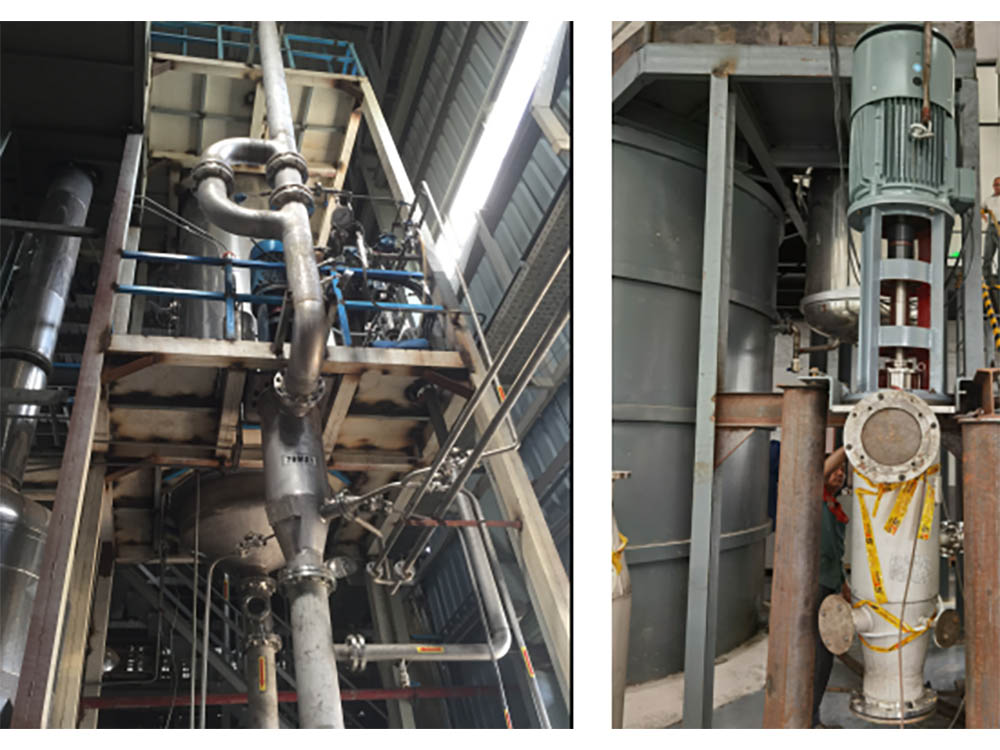

SO3 gas goes through SO3 filter with precise concentration (%), then reacts with organic raw material in the reactor. The reaction heat is removed by recycle cooling water in the reactor shell side. The exhaust gas goes to the exhaust gas treatment unit by passing the gas-liquid separator and cyclone separator; the organic acid goes to aging and stabilization unit or neutralization and dioxane stripping unit.

The flow rate of organic raw material is controlled by a mass flow meter and control valve (or VFD of gear pump); the liquid level in the gas-liquid separator is controlled by a level transmitter and VFD of discharge pump; the flow rate and density of organic acid are detected by a mass flow meter and its density is cascade controlled to adjust the raw material flow rate. The recycle cooling water inlet temperature remains constant by supplement water; cooling water flow is adjusted by the control valve, whose rate depends on the water temperature difference of the reactor in each path.

Features: WEIXIAN has more than three important improvements to increase the reliability of the reactor. Meanwhile, the size of each reactor tube, distributor, and nozzle is in high uniformity. The reactor tube is treated by high precision rolling and oxygen-free annealing process, which makes the finish degree of all tubes and each part of the tube of high uniformity. Compared to the competitors' technology, our plant has longer continuous running time and lower dioxane when producing SLES.

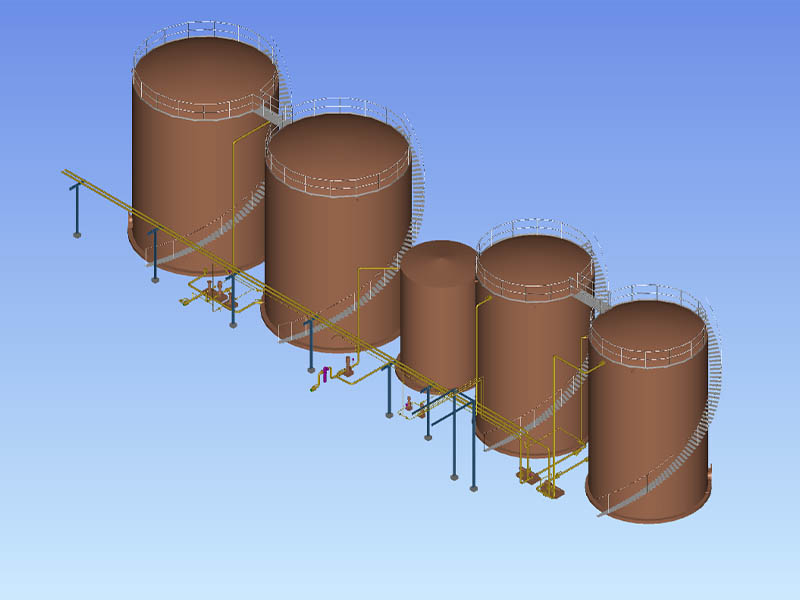

The LABSA (linear alkyl benzene sulphonic acid) from the separator goes to the aging vessel by first discharge pump, then stabilized in the stabilization pump with water. After cooling, the LABSA will be pumped to the finished product tanks by the second discharge pump. The liquid level of the aging vessel is controlled by a level transmitter and VFD of the second discharge pump.

Features: WEIXIAN aging vessel is a vertical and static mixing type, with no back-mixing and the aging time can be controlled, which makes it closest to the theoretical limit of aging conversion rate, and reduces the free oil content and sulfate acid content to the minimum, while correspondingly improves the active matter content close to or reach 98%.

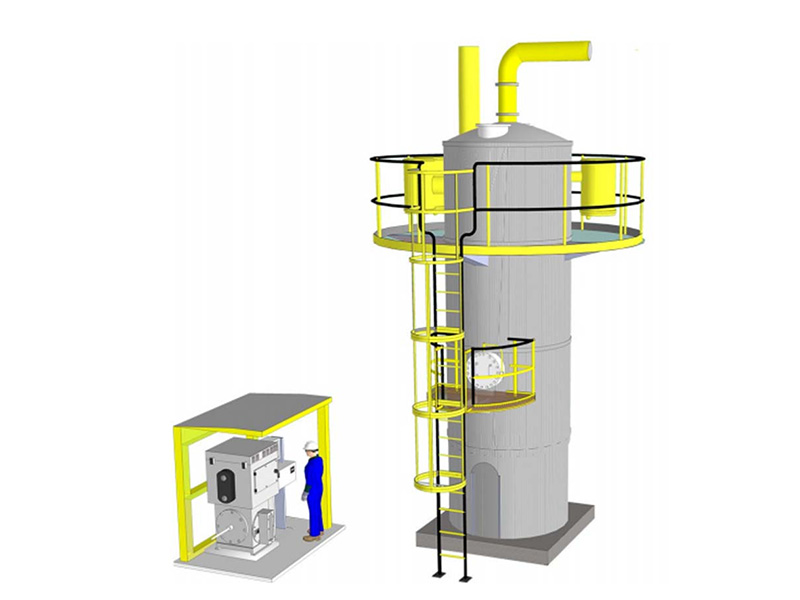

Before discharge, organic acid mist and SO3 will be removed from the exhaust gas by ESP, SO2 will be removed by the scrubber.

Features: WEIXIAN adopts plate-type tubes as the cathode of ESP. Compared with using steel wire as the cathode, it never needs maintenance.

When producing SLES, the sulfate needs to be neutralized with pure water, caustic soda, H2O2, and buffer in the neutralization reactor, all materials react by high-speed mixing, then remove dioxane together with air in the stripping tower under vacuum condition, meanwhile, the cooling procedure is also done in this tower.

Features: Compared with Italy's vacuum neutralization, WEIXIAN stripping tower is a static equipment, without motor and maintenance requirement. Before going into the stripping tower, products react in the micro positive pressure reactor, so there is no acid gas corrosion happened in condensate and vacuum pump. Meanwhile this unit has a 10 times SLES recycle loop, comparing to similar technologies of other suppliers, this process makes the neutralization temperature rise less than 5℃, which helps us to get the products with lighter color, more stable pH value and lower dioxane content. This unit is able to realize ultra-low dioxane content.

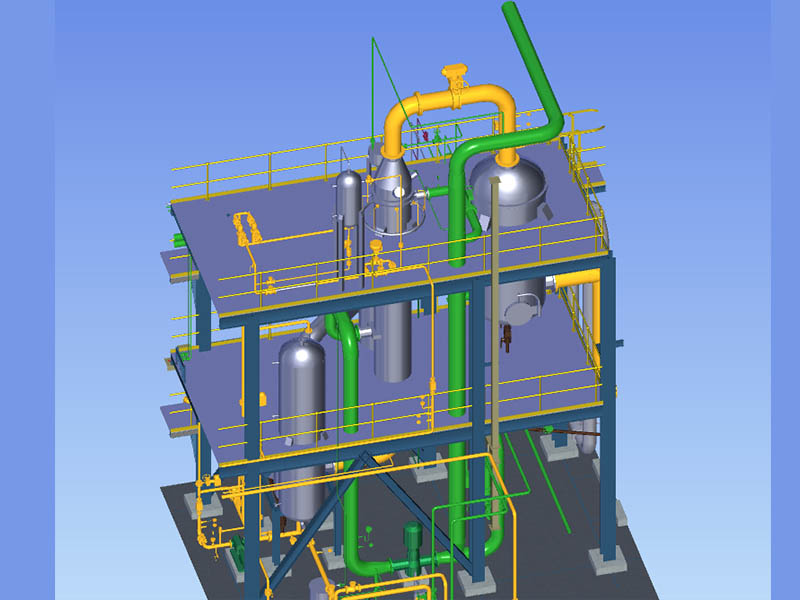

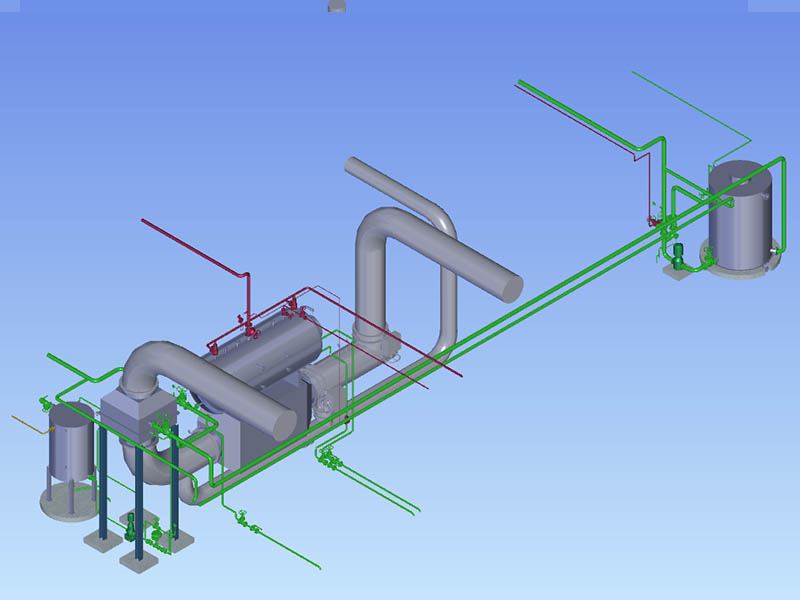

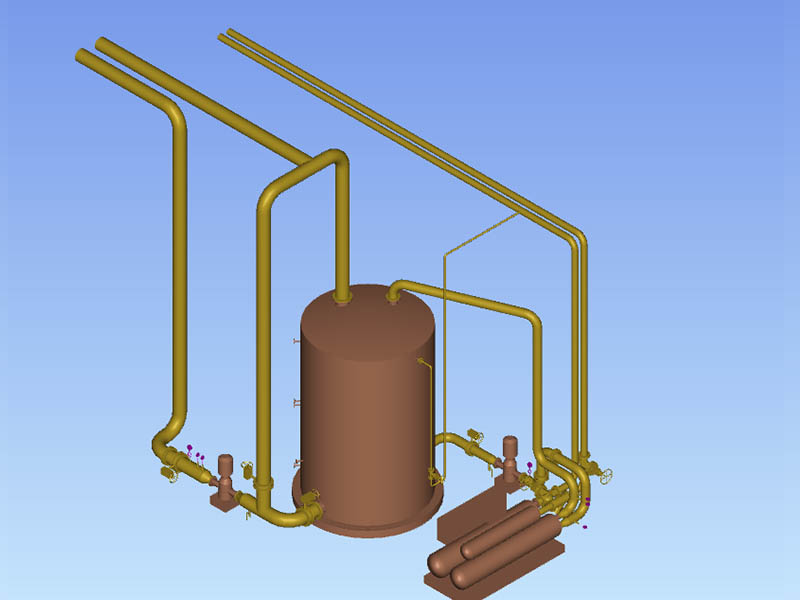

Hot air firstly goes into the heat-pipe exchanger, the heat is transferred to the soft water inside, and steam of 0.4~0.6Mpa is generated. After passing through the heat-pipe exchanger, hot air is reused to pre-heat the R/O water and generate the hot water.

Features: With the waste heat recovery system, the plant doesn’t need external steam upon cold start-up. During normal operation, plants realize steam and hot water self-sufficient.

When producing SLS, the organic sulfate needs to be neutralized. In Unit 07, pure water, caustic soda, hydrogen peroxide solution, buffer, and organic sulfate are pumped to the neutralization reactor, after high-speed mixing, transported to the SLS cooler, then SLS finished product is produced.

Features: In the neutralization reactor, SLS has 10 times circulating reflux, which enables the temperature increase in neutralization reaction within 5℃. The products appearance is more transparent, pH value is more stable.

The Sulfolactone hydrolysis system consists of a boosting pump, three heat exchangers, and a hydrolyzer. After aging, α- Olefin sulfonate is pumped to the neutralization reactor. α- Olefin sulfonate, pure water, caustic soda, hydrogen peroxide solution, and buffer are pumped to the neutralization reactor, after high-speed mixing, materials were pumped to the two heat exchangers and a hydrolyzer in sequence. After hydrolyzed, the finished product AOS is produced.

When AOS is produced, the temperatures at the top of the sulfonation reactor, aging vessel and α-olefin inlet need to be decreased to ensure product stability. A chilling water unit is required. The chilling water unit consists of a chilling water group, chilling water tank, and two circulating pumps. One circulating pump transports the water to the chilling group, decreasing the temperature to the set point, then backflow to chilling water tank; the other circulating pump transports the chilled water to the user, then backflow to chilling water tank.

Normally, in the LABSA field, there are two tanks of alkylbenzene (LAB) material tanks, two LABSA tanks and one liquid caustic soda tank, and equipped the transfer pumps for material, finished product and liquid caustic soda. If the plant is for producing multiple products, then corresponding tanks and pumps are needed. Such as AEO tanks, SLES tanks, AO tanks, AOS tanks, Fatty alcohol tanks , SLS tanks, etc.

WEIXIAN sulphonation/sulfonation plants represent the highest level in the industry. So far, we can provide from a one-tube pilot plant to 10t/h mass production plant. Among 200+ projects we have done, the majority of them were turnkey basis, including but not limited to:

· LABSA (sulfonic acid) production line

· SLES production line

· SLS production line

· AOS production line

· HABSA production line

· MES production line

· SLS/AOS/sulfonic acid sodium salt drying units

· Other anionic surfactant production lines

By adopting state-of-the-art designs and processes, all the performance aspects including plant reliability, finished product qualities, and unit raw material/power consumption are superior to that of competitive plants.

WEIXIAN sulfonator adopts multi-tube falling film reactor. Capacity range is from 1-tube to 240-tube (10t/h). Since 1995, WEIXIAN has supplied hundreds of sulfonators, including 20+ with the capacity over 5t/h. WEIXIAN has successfully applied two world largest 7.5t/h sulfonators in by 2023.

1. Organic material distribution system in the head of reactor

After calibration, the flow deviation reaches ±1.5%. The distribution head and nozzles are one-time clamped processed and formed by a CNC machine to ensure that the tolerance of major dimensions reaches ± 0.005mm, and minor dimensions ± 0.01mm.

2. Finish degree of reaction tube inner wall

Regarding the reaction tubes, high precision cold rolling and annealing are applied, and processed under a 1040℃ vacuum condition to remove inter-molecular stress. Those treatments make sure the inner and outer surfaces’ finish degree of each tube reaches level Ra0.4 (like a mirror); the deviation of the inner and outer diameter of the reaction tube is controlled at less than ± 0.02mm.

3. The welding and flaw detection method of the distribution head and the reaction tube

High-frequency welding + argon arc welding are applied between the distribution head and the reaction tube. The welding form is fillet welding. The flaw detection method is nondestructive testing. For each tube, we applied 0.6Mpa hydrostatic test and endoscopic exploration for weld formation and inner pipe accuracy testing.

4. Concentricity of three tube sheets

All three tube sheets are processed with the same coordinate in the machining center. Tube concentricity tolerance reaches ± 0.01mm. All three tube sheets will be stacked and fixed together according to the installation position and checked each holes by inspection mandrel one by one with concentricity deviation less than ± 0.01mm.

5. Sealing reliability

5.1 The cooling water sealing between the shell side upper section and middle&lower section

The cooling water enters into the second and third parts and exits from the third part of sulfonator. The first (upper) part has to be strictly isolated to ensure the separated circulation of chilling water (15℃), which is crucial for better product quality, especially for AOS.

5.2 The two-way sealing between sulfonator upper part SO3 and organic material

In tube sheet 1, the compressing screw head adopts a combined screw head + three combined gaskets type, which forms a reliable two-way sealing. It realizes 100% isolation of the oleum and prevents rusting and leaking.

5.3 The sealing of cooling water between the distribution head and shell side

Adopting a new type of sealing structure greatly improves the pressure resistance of the shell side. The shell side test pressure can be greater than 0.6Mpa, and the water is able to return with pressure. All sealing parts are made out of special fluororubber O-rings, with 100% sealing efficiency, and lifetime replacement free.

5.4 The sealing of cooling water between the reaction tube’s lower part and the shell side

Applied fluororubber O-rings, the sealing efficiency is 100%, and lifetime replacement free.

6. Other Technical advantages of our sulfonator

6.1 Extended operation period: LABSA continuous production period reaches 40+ days;

6.2 70% SLES continuous production period reaches over 3 months;

6.3 AOS continuous production period reaches 25+ days;

6.4 Easy sulfonator calibration:

First start-up flow deviation is able to reach ±1.5%. The thickness of replacing gaskets are from 1.8~2.2mm (standard thickness is 2mm). Top level products quality and extended sulfonator washing interval can be ensured.

6.5 Yield flexibility:

LABSA capacity adjustment range 55%~115%

70% SLES capacity adjustment range 80%~140%

It adopts the cathode plate hollow-out design to avoid “black acid” accumulation. Cathode SS wires are replaced by SS tubes, in order to eliminate the risk of breaking.

The working voltage is 40,000 V, featured in excellent SO3 and organic acid mists removal performance.

Unlike the former rotating type with an agitator, ours is a static type, which is featured in more homogeneous aging effect with no back-mixing.

By adopting a special inner structure, each material molecular in the static aging vessel will have equal residence time (staying time). On the contrary, the residence time of each molecular in a rotating aging vessel is uneven, which shows a normal distribution. Our aging time is adjustable from 0-60 minutes by controlling the liquid level in the vessel. Normally, the aging time is set to be 30 minutes; when a higher active matter percentage is required, for example, 97.5% - 98% LABSA, the aging time can be set to 45 - 60 minutes. Besides the performance, power consumption and maintenance requirements are reduced due to the nature of static equipment.

Stripping tower 79T1 is static equipment, without motor or rotating parts. Compared to outdated technology, our stripping tower doesn’t need maintenance. WEIXIAN designs the stripping tower based on the characteristic of sulfonated/sulphonated products. In the stripping tower, degassing, water removal, dioxane stripping, and cooling can be achieved in the same equipment, which can save power consumption, and ensure stable running and product quality.

The high-shear neutralization reactor is composed of multiple high-speed dispersing shearing discs, and the mechanical seals and bearings are all customized for high-speed mixing/shearing purpose. Stable operation at 960 rpm.

The neutralization reactor has the advantages of efficient and uniform mixing, flexible operation, stable system pressure, and low failure rate.

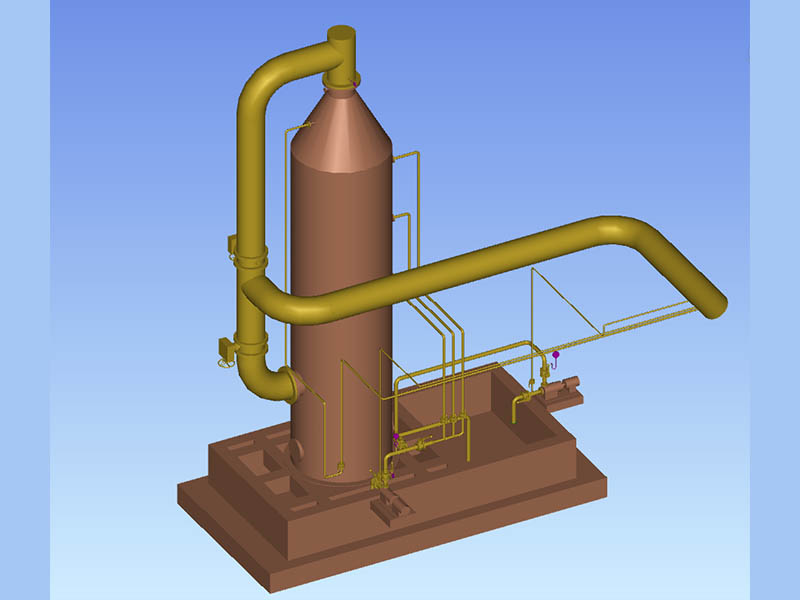

The conversion tower adopts vertical SS304 stainless steel packed structure with a temperature resistance of 700°C.

It is featured in stable conversion rate, flexible operation and temperature control, and maintenance-free. Four-layer packed tower, each layer is filled with V₂O₅ catalyst, which is a combination of low-temperature and medium-temperature catalysts, which can not only maintain the advantage of low light-off temperature but also ensure a conversion rate greater than 98%. This feature greatly improves the start-up preheating efficiency and shortens the preheating time.

There are corresponding thermometer interfaces on the top and bottom of each bed to precisely control the temperature and ensure the conversion efficiency. Each bed has a manhole for on-site catalyst loading.

The heat-pipe exchanger has high heat transmission efficiency. The equipment also has a compact structure, and small thermal side flow resistance. Its structure is safe, reliable, and better than the heat exchanger of other structures, and the damage of a single (or few) heat pipe will neither affect the overall performance of the equipment nor affect the plant production. The waterway is outside the flue, so it requires no shut down for replacement and overhaul.

Design life is 10 years plus. This equipment is used in combination with the start-up pre-heater, which produces steam before cold start-up, external steam supply is no needed.

The recovery rate is 100kg sulfur burning generates 250kg steam. The first/second stage recovery of exhaust gas generates steam, and the third stage recovery produces hot water with efficiency of 36.5%, 44.2% and 67.3% respectively.

Our Control System adopts Siemens, ABB, Supcon, Hollysys, Honeywell or equivalent brands.

We adopt on-site instruments from international brands, such as massflow meter from Emerson; dewing point meter from Michelle; pH meter from Mettler Toledo; transimitter from YOKOGAWA etc.,Major electrical components are all internationally famous brands such as SIEMENS, SCHNEIDER, or ABB.

The whole plant will be fully automatically controlled at a high level. We have in-house engineers for the programming and configuration. Remote operation parameter adjusting can be realized, if get the permission from the owner.

The hot air generated from the first layer of the converter and SO3 second cooler can be used for silica gel regeneration, extra hot air produces steam and hot water for raw material and finish product heat tracing. Then partial remaining hot air (100℃) further goes to Unit 38 to treat the wastewater coming from the scrubber. Crystal Na2SO4 hydrate will be produced by oxidizing the NaSO3 and Na2SO4, and evaporating water in the wastewater. Therefore, the plant can realize ZERO wastewater discharge from scrubber.

The main reaction heats from the sulfur furnace and the converter generate steam directly by using a fire-tube boiler.

Compared with the traditional technology, this process generates twice steam. Apart from being used in the sulfur melting unit, the steam can fully fulfill the requirement of chilling in air drying unit by replacing the electric driven chiller with steam driven lithium bromide chiller for generating chilling water. The power consumption can be 15% lower.

Patented revolutionary technology. It circulates the system exhaust gas from the ESP outlet to the main process air, raises gas pressure and adds oxygen, then goes through the process of sulfur burning and conversion, sulfonation, and exhaust gas treatment. It manages to reuse the exhaust gas discharged from the ESP, and reduces the exhaust gas discharged to the atmosphere by 96% (meaning only 4% actual emission compared with the traditional process). Meanwhile, this process reduces the caustic soda unit consumption by 7kg on 100% basis, and 2-3kg sulfur.

Recent years, Weixian is keep focusing on ULTRA-LOW dioxane technology. Based on the previous Unit 79 Neutralization and Dioxane Stripping process, Weixian has newly developed the Unit 89 Dioxane Multi-stage Stripping process, which realizes 65% - 99% dioxane removal rate depending on the needs. With this innovative technology, less than 1ppm dioxane content can be truly realized no matter the raw material EO Number and initial dioxane level.

Unit 89 is a continuous process. Dioxane level from 15ppm to 1ppm (70% A.M.) by Unit 89 only cost about 15 USD operational cost for per ton product.

Therefore, we proudly announce that any regulation of dioxane level is no longer a problem anymore.

Please contact us for quote.

In addition to focusing on technology, we also attach great importance to technical services and training for customers. No matter where our customers are in the world, we can respond to their needs and problems within 10 hours. Technicians can be dispatched to anywhere in the world within 72 hours. Thanks to the reliability of the plant, WEIXIAN sulphonation plant can achieve an operation rate of 330 days / year. All plants have one-year guarantee period. Meanwhile, we will advise customers to purchase our standard spare parts kit to facilitate the timely replacement of vulnerable parts; the spare parts kit shall be provided at the cost price.

WEIXIAN’s technical services are including:

1. Free technical consultation.

2. Feasibility study in the early stage of the project.

3. Quotation and proposal of turnkey sulphonation plant and equipment.

4. Renovation and revamp of old sulphonation plant.

5. Design and engineering of customized turnkey sulphonation plant and equipment.

6. Installation of the plant.

7. Remote or on-site technical supports and commissioning.

8. Training of the buyer's technical personnel.

9. Other technical services related to sulphonation.

OVER 30 YEARS HISTORY

CARRIED OUT OVER 200 PROJECTS

Supplied The World Largest 8T/H Plant

COVERED 17 COUNTRIES IN THE WORLD