WEIXIAN Sulfonator Introduction

Jun 26, 2024

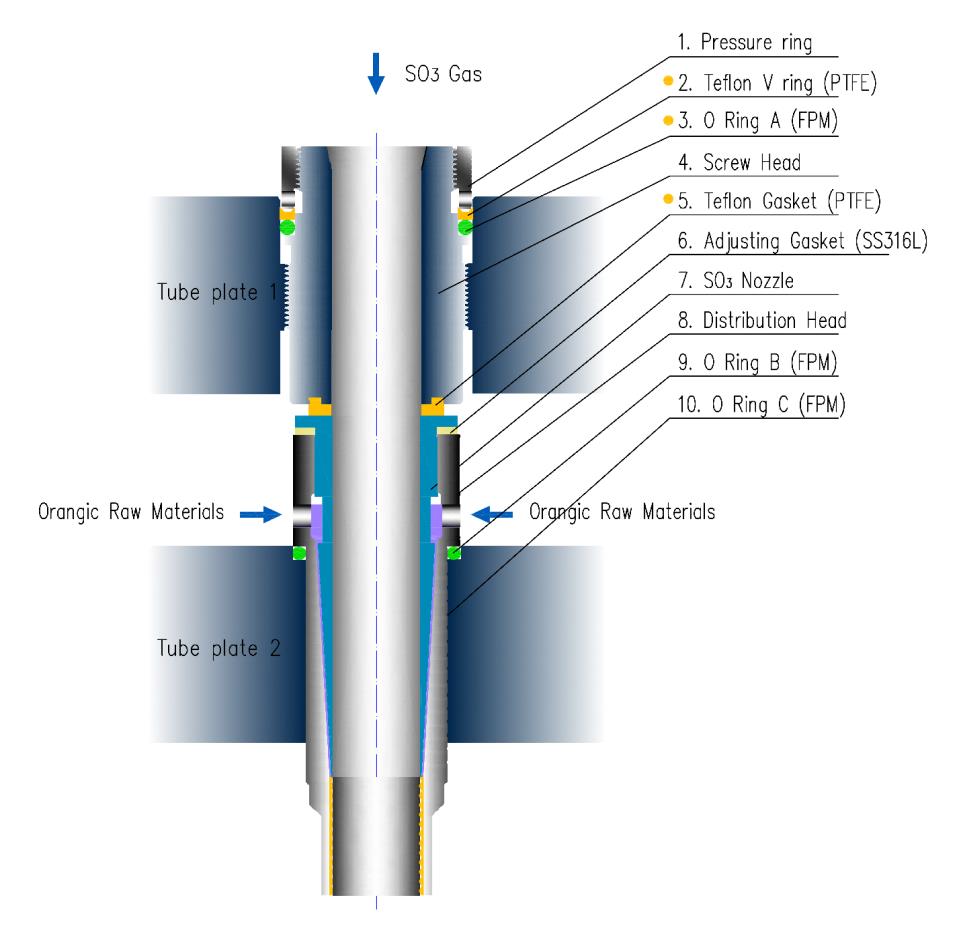

Sulfonator is the core equipment of a sulphonation plant, WEIXIAN Reactor adopts multi-tube falling film type. The organic raw materials entrances are between the Tube-sheet 1&2, the organic raw materials in the reaction tube form a uniform film, and reacts with SO3 gas (2.5- 7%). The reaction emits a large amount of heat which is removed by heat exchange of chilling water or cooling water in the shell process.

There are currently mainly 5 types of organic raw materials, which are:

1. LAB/ alkyl benzene for LABSA

2. AEO1, AEO2 or AEO3/ Fatty alcohol ether for SLES- 1EO/2EO/3EO

3. AO/ α olefin for AOS

4. FA/ fatty alcohol for SLS

5. HAB/heavy alkyl benzene for HABSA

The capacity range of WEIXIAN sulphonators is from 1 tube to 240 tubes (1 - 10t/h). So far, WEIXIAN has supplied hundreds reactors, including two world’s largest 7.5t/h 180-tube reactors.

The technical advantages of WEIXIAN sulfonator:

Ø The organic material distribution system

1. The reactor calibration can easily reach ±1.5% deviation, which makes the first start up much simpler and results in better product quality.

2. The distribution heads and nozzles are machined in a single clamping process in a CNC machining center to ensure that the tolerance of the main dimensions reaches ±0.01mm.

Ø High finish degree of each reaction tube surface

Special manufacturing processes are applied, the reaction tubes are processed under a 1040℃ vacuum condition to remove inter- molecular stress after high-precision cold rolling , which makes sure the inner and outer surfaces’ finish degree of each reaction tube reaches Level Ra0.4 (like mirror) with high consistency, benefited from perfect surface finish, consistent molar ratio of the entire reaction can be ensured and side reaction can be reduced greatly, this is crucial in regards of minimizing dioxane content in SLES and reducing the organic acid content in exhaust gas.

In addition, the tolerance of the inner diameter and outer diameter of the reaction tube is controlled within the range of ±0.04mm.

Ø Welding points and Pre-factory testing

The welding points between the Reaction Tube and the Distribution Head are moved up to skip the reaction initial part, and butt welding is changed to fillet welding. Therefore there is no weld on the entire 6-meter Reaction Tube, shallow leakage at reaction initial part can be avoided, and the reliability is greatly improved.

Each reaction tube is subjected to 0.6Mpa water pressure test and endoscopic probe to check the weld molding and inner tube precision before leaving the factory.

Ø Concentricity of the three tube sheets

Three pieces of tube sheets must be machined with the same coordinates in the machining center. The concentricity tolerance of the processed pipe holes reaches ±0.01mm. After the completion of manufacturing, the three pieces of tube sheets are stacked and fixed together according to the installation position, and checked hole by hole with the concentricity deviation of less than ±0.02 inspection mandrel.

Ø Reliability of multiple seals in the sulfonator

1. Cooling/chilling water sealing in shell process: cooling/chilling water is fed into two inlets and discharged through three outlets after heat exchanging; the upper section is strictly sealed to ensure that the upper section circulates the chilled water (15°C) separately without leakage. This is especially important in the production of AOS.

2. The head of sulfonator adopts two-way sealing of SO3 sealing and organic material sealing: the compression screw head of the tube sheet 1 adopts a combination of screw head + three combination gaskets to form a reliable two-way sealing, which realizes 100% reliable isolation of oleum and elimination of rusting and leakage.

3. Distribution head and shell process cooling water sealing:

With the use of new sealing structure greatly improves the pressure resistance of the shell process, shell process test pressure reaches 0.6Mpa or more. All sealing parts are made of special fluorine rubber O-ring, with 100% sealing efficiency and lifetime without replacement.

4. Lower section of reaction tube and shell process cooling water sealing: adopts Viton O-ring sealing, 100% sealing efficiency, lifetime without replacement.

Other advantages:

1. Long extended washing interval: continuous production of LABSA can reach more than 40 days, more than 3 months for SLES production and more than 25 days for AOS production.

2. Easy calibration of reactor: ±1.5% deviation of flow rate at the first start-up, and the range of gasket replacement is 1.8-2.2mm (base thickness is 2mm), which ensures the quality of sulfonated products and extends the cleaning cycle of the reactor.

3. Yield Flexibility: Capacity adjustment range 55% ~ 115% for LABSA production; Capacity adjustment range 80% ~ 140% for SLES 70% production.